Page 1 - Magnesium Anodes

P. 1

Magnesium Anodes

ISO 9001 Certified

ISO 17025 Accredited cert. #3612.01

Galvotec's experience, since 1984 producing sacrificial (galvanic) anodes assures that you will

receive, the highest quality anodes in the industry, that will effectively mitigate corrosion when used in

a properly designed and maintained cathodic protection system

Galvotec Magnesium Anodes are produced in a wide variety of shapes and sizes for use in brackish or

freshwater cathodic protection systems (Magnesium Anode may also be used in specific sea water

applications)

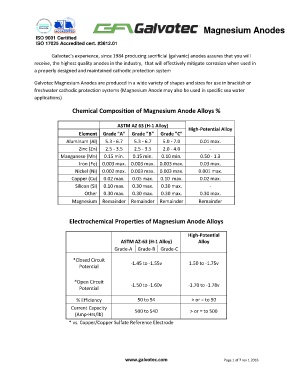

Chemical Composition of Magnesium Anode Alloys %

ASTM AZ 63 (H-1 Alloy) High-Potential Alloy

Element Grade "A" Grade "B" Grade "C"

Aluminum (Al) 5.3 - 6.7 5.3 - 6.7 5.0 - 7.0 0.01 max.

Zinc (Zn) 2.5 - 3.5 2.5 - 3.5 2.0 - 4.0 -

Manganese (Mn) 0.15 min. 0.15 min. 0.10 min. 0.50 - 1.3

Iron (Fe) 0.003 max. 0.003 max. 0.003 max. 0.03 max.

Nickel (Ni) 0.002 max. 0.003 max. 0.003 max. 0.001 max.

Copper (Cu) 0.02 max. 0.05 max. 0.10 max. 0.02 max.

Silicon (Si) 0.10 max. 0.30 max. 0.30 max. -

Other 0.30 max. 0.30 max. 0.30 max. 0.30 max.

Magnesium Remainder Remainder Remainder Remainder

Electrochemical Properties of Magnesium Anode Alloys

High-Potential

ASTM AZ-63 (H-1 Alloy) Alloy

Grade-A Grade-B Grade-C

*Closed Circuit -1.45 to -1.55v 1.50 to -1.75v

Potential

*Open Circuit -1.50 to -1.60v -1.70 to -1.78v

Potential

% Efficiency 50 to 54 > or = to 50

Current Capacity

(Amp-Hrs/lb) 500 to 540 > or = to 500

* vs. Copper/Copper Sulfate Reference Electrode

www.galvotec.com Page 1 of 7 rev 1 2016